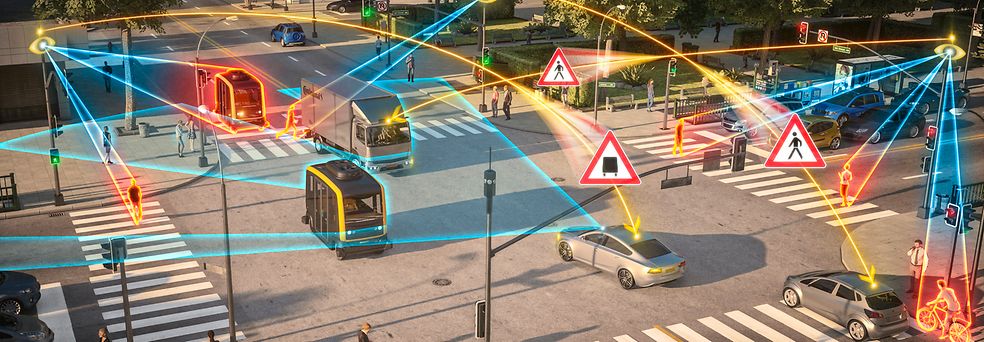

| End-to-End Connected Car Networks: paving the way for smart and autonomous mobility as well as software-defined vehicles

All major trends in the automotive industry including smart and autonomous mobility and software-defined vehicles require two decisive pillars: a reliable, high-speed, and ultra-low-latency connectivity to the outside world as well as a high-performance computing unit to process all the data coming into the vehicle. Continental will demonstrate for the first time its End-to-End Connected Car Networks solution at the upcoming Auto Shanghai, which addresses both these two requirements.

Continental designs its own 5G Network Access Device to enable the 5G next-generation connectivity which realizes reliable, fast, and ultra-low latency vehicle connectivity. It offers scalable processing power, enhanced cybersecurity, and supports different hardware options to ensure the highest connectivity standard. Continental also provides flexible system integration options for OEMs and Tier 1 suppliers, from standalone Network Access Devices or full-scale integration into the Telematics Control Units or Intelligent Antenna Modules. Continental is already working with several global automotive manufacturers for 5G telematics based on its successful 5G Hybrid V2X platform.

A profound transformation of the vehicle’s E/E architecture coming along with a shift towards high-performance computing units is key to realize smart, safe and autonomous mobility. With the Body High Performance Computer, Continental builds the foundation for fully connected vehicles, as it manages data streams in the vehicle and serves as an intelligent interface to the Internet of Things (IoT). Furthermore, it also has the capability of cross-domain function integration including specific ADAS L2 functions. As the first Tier 1 supplier, Continental has brought a Body High Performance Computer into series production as the In-Car Application Server (ICAS1) for Volkswagen’s ID. electric vehicles.

Diversified solutions to make the mobility more convenient

Continental has continuously developed multiple solutions to deliver a more convenient and enjoyable user experience.

Continental brings the 3D Lightfield technology into a curved screen for the first time. The 3D Lightfield Curved Instrument Cluster simplifies human-machine interaction in the vehicle and enhances driving safety while further enhancing the flexibility of cockpit design. The 3D Lightfield technology enables all passengers in the vehicle to enjoy a 3D experience without special glasses or head tracker cameras. Visually, the 3D elements protrude up to ten centimeters from the display, making them pleasant to perceive but not irritating.

Continental and its partner Leia Inc. co-developed the first natural 3D Lightfield display in 2019 and integrated the technology in the center console in 2020. Now, both parties are bringing the 3D Lightfield technology into curved displays. Both the curved display design and the ability to display the cockpit in natural 3D significantly increase the visual and ergonomic design freedom, upgrade the experience of human-machine interaction to a new level.

Continental also presents a new modular and scalable contact sensor to detect scratches and damages. Structure-born and airborne sound are signals which provide valuable information about the immediate vehicle surrounding. The Contact Sensor System (CoSSy) is specially developed to pick up the sound patterns of a number of types of contact. If a parked car gets dented or scratched, the CoSSy sensors can give the incident a time stamp. The sensor signal could also be used to wake up the appropriate camera to take a picture of the situation or to make the other driver aware of the contact by sounding an alarm or sending information to a known smartphone. This would help to deter people from vandalism and to avoid unintentional hit-and-run situations. Rental car companies could easily check the car status as “undamaged” when the vehicles are returned.

The high-speed rotor position sensor measures the angular position of the rotor shaft in synchronous electric motors. The sensor signal is required for an efficient e-machine torque control used in electric and hybrid vehicles. This compact and slim sensing solution combine several functions, and its robust, overmolded PCB-less design can be easily mounted at the end of the rotor shaft.

Being lightweight is a major feature of Continental’s line solutions. In terms of driving, the lightweight vehicle can not only improve fuel economy and reduce emissions but also significantly improve the overall acceleration. For example, the turbocharger lubrication line displayed at this year’s trade show has achieved further weight reduction by using aluminum instead of steel, which can improve the power performance as much as possible with the reduced weight to achieve more flexibility mobility efficiency. Continental also uses high-performance plastics in the engineering of its lines. Besides, many functional components, like sound-absorbing resonators, can also be integrated into plastic lines in an easier way. The lightweight air induction hose line with a sound-absorbing resonator helps to improve the NVH performance with an average noise reduction of 20 dB and enables the drivers and passengers to further enjoy the pleasure brought by the lightweight solutions in the convenient mobility. |